Small houses have to make good use of their spaces. The space in the pic up above just looks like it’s missing something. It’s a void, dead space, and small houses abhor a vacuum. You can fill the void with trash cans and cat food and old woodworking projects but is that really the best use of that space? Why don’t the kitchen countertops extend all the way down that wall? I don’t know why they didn’t just do it that way, but I also don’t know what used to be there when they originally built those cabinets. Maybe that’s where they put the washer and drier. Maybe they kept dead bodies there in boxes. I don’t know, but for some reason they didn’t see fit to build out the kitchen cabinets for more countertop space and more storage.

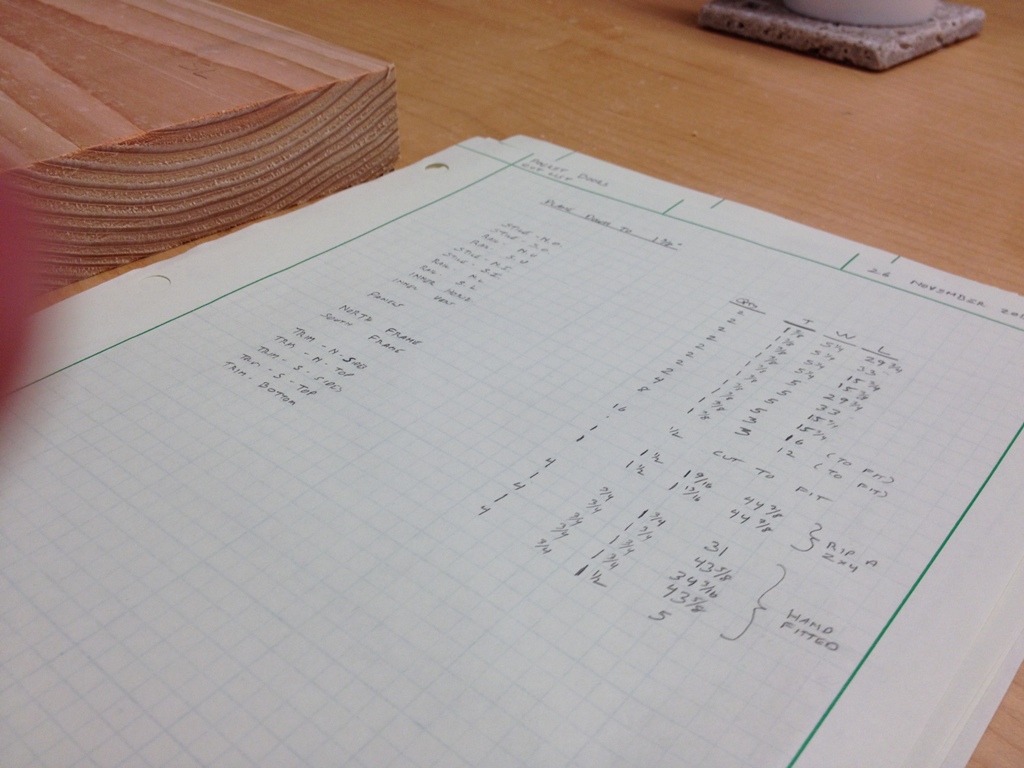

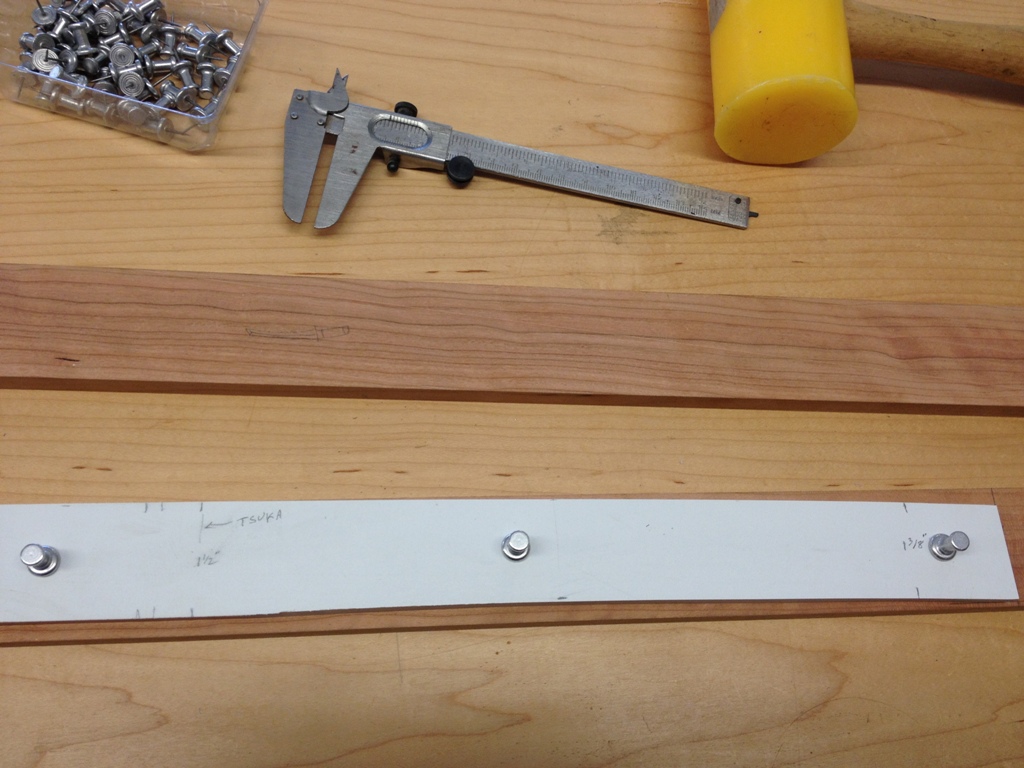

That’s where all this lumber comes in. I can use this to make more cabinetry in that space and then we can extend the kitchen countertop so it runs the full length of the wall. I got some solid planks of birch and a couple sheets of high grade birch plywood. Birch is the most boring wood on the planet. It is bereft of character, does not like to be stained, and as hardwoods go it is one of the softer ones. But the existing cabinets are birch and if I want to match them (part of me does, and part of me doesn’t) then I have to use boring ol’ birch.

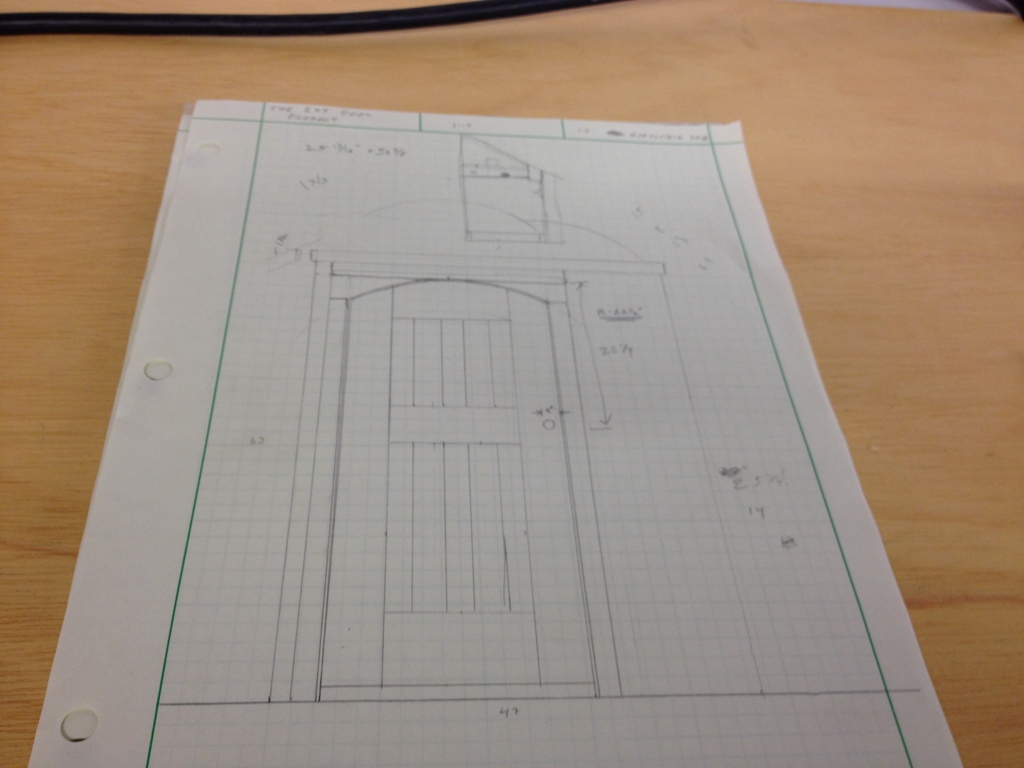

I started with the base, so I have a nice foundation to set everything on. There will be three cabinet areas, two of which will house the garbage and recycling containers and one will be New Storage which we can put New Things into. That’s very exciting to me. And I’ve made these with room to sit at the countertop like a bar. It faces the tv, so you can grab some snacks and a cold beer and watch hockey all in one place. Life doesn’t get much better than that.

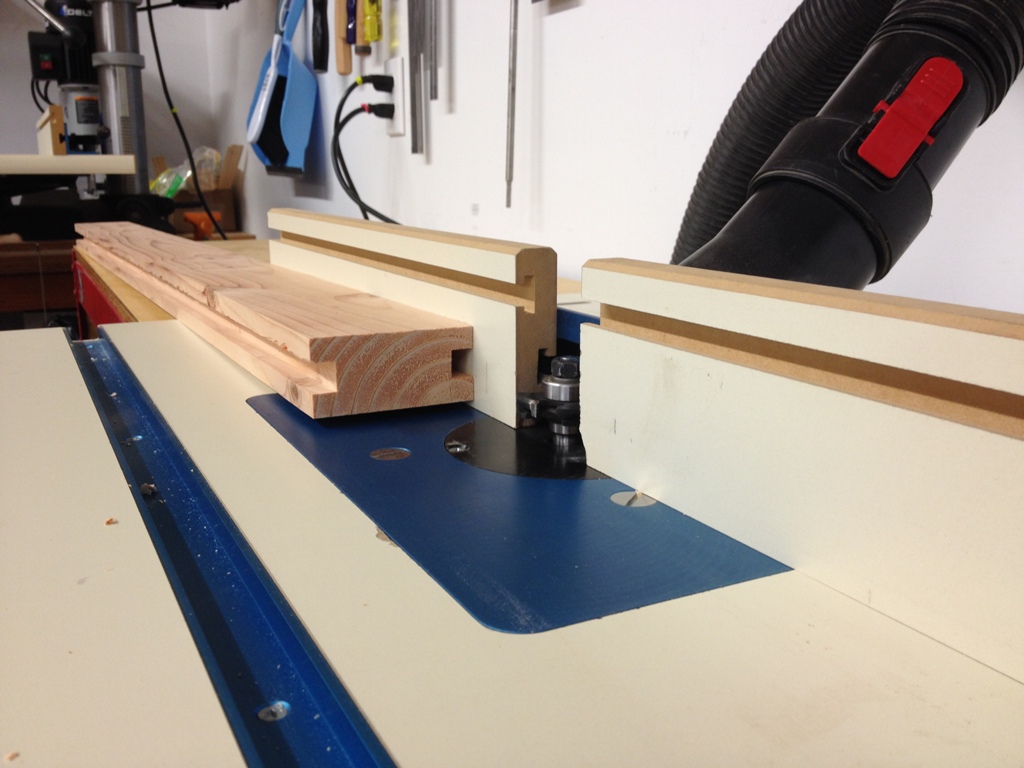

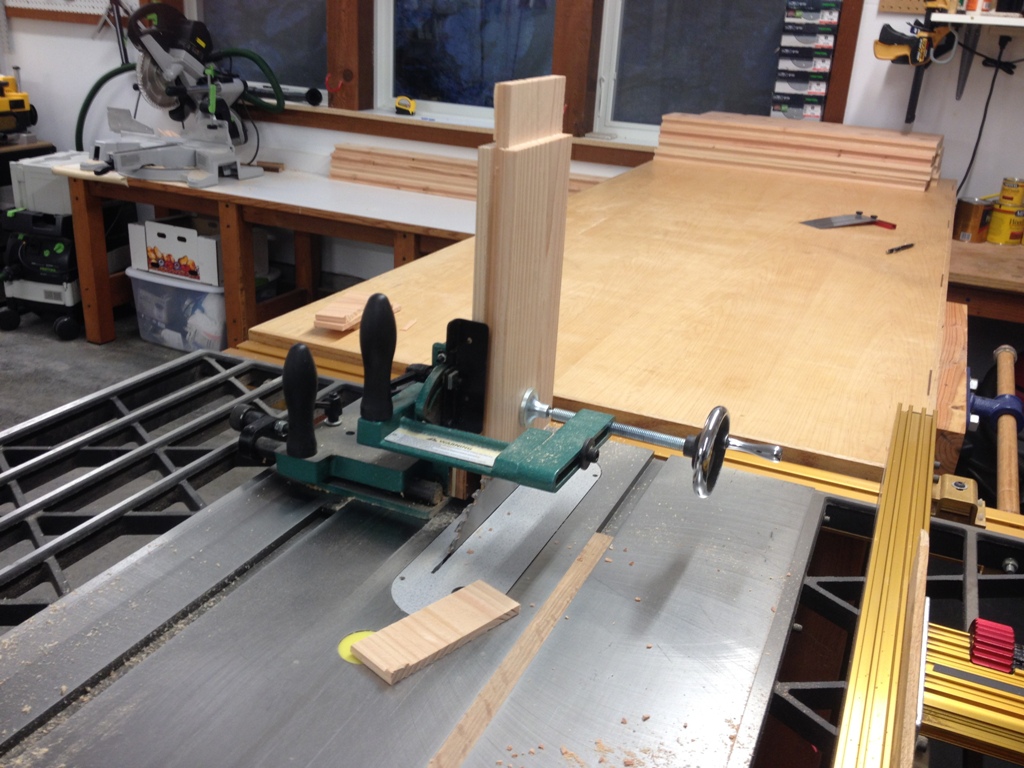

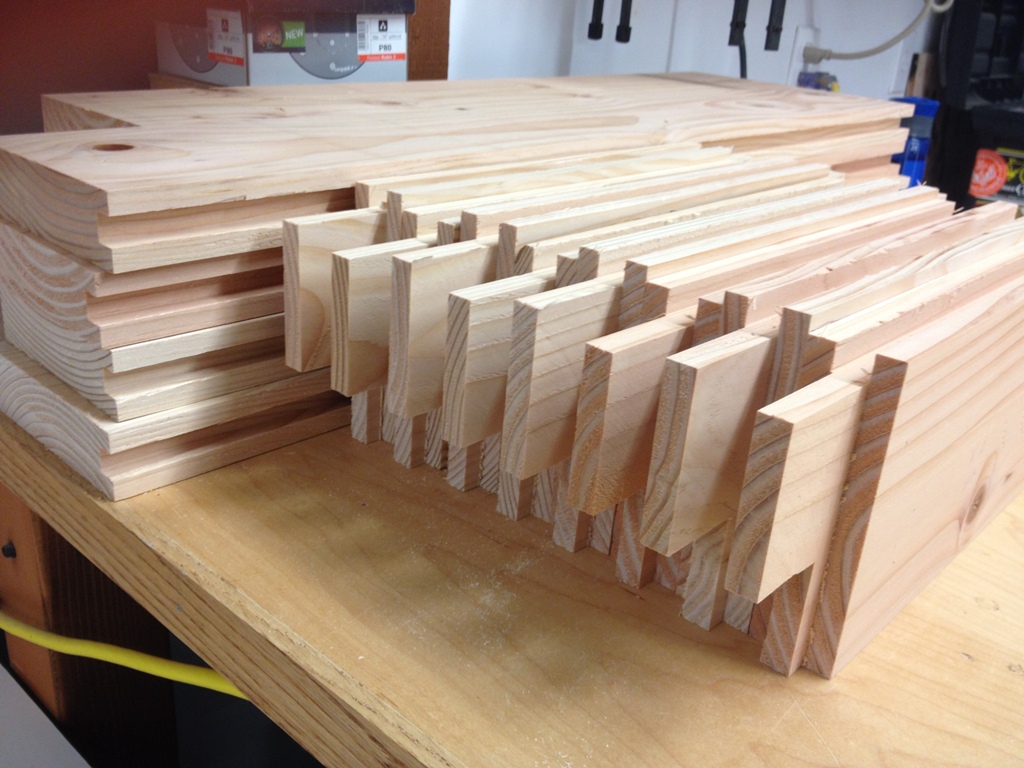

The wood chopped up readily enough. A little burning but I kind of have a crappy saw so that’s to be expected. My last project was made with 2×6 beams so it is nice to work with a wood that’s flat and square and doesn’t have a bunch of knots in it.

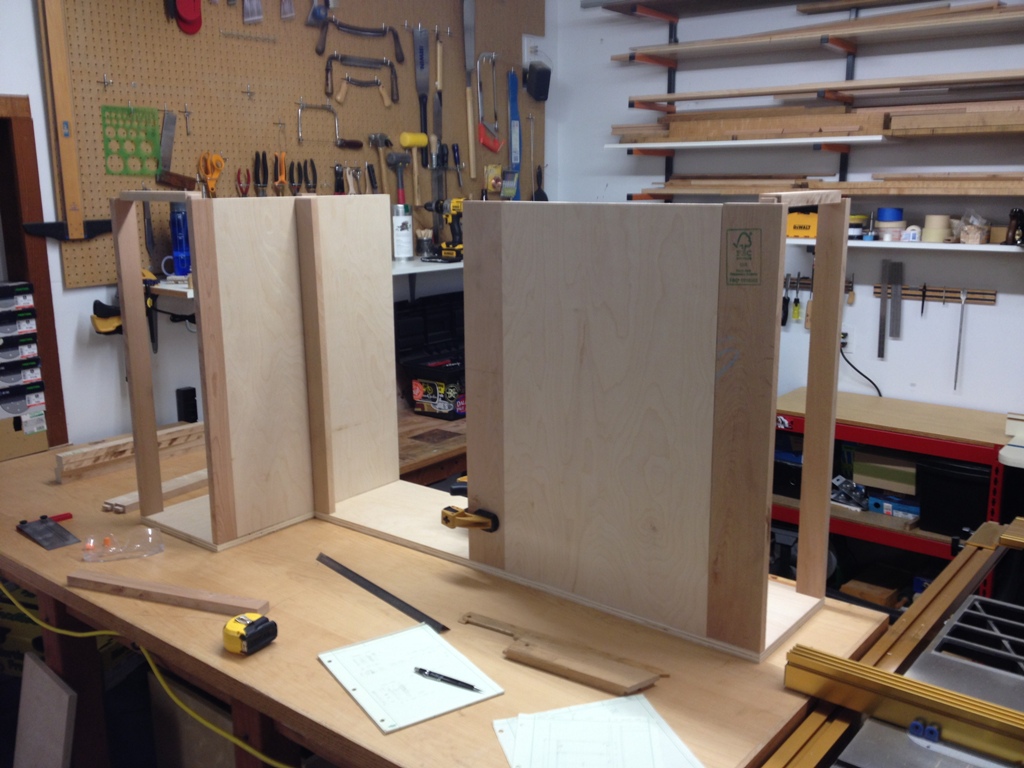

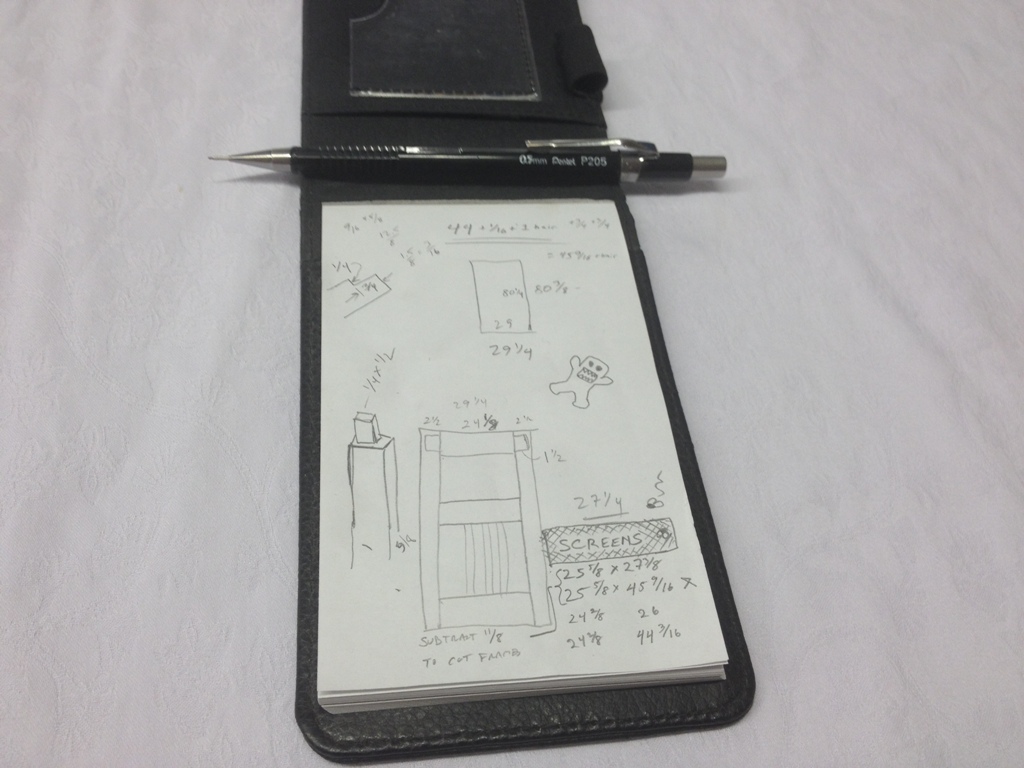

And here’s a really preliminary dry fit of all the pieces I’ve cut so far. It’s so important to me to fit everything together as soon as possible just so I can see the scale of it. Sometimes when you look at something in a live, 3 dimensional scale, you miss things that you didn’t see when you drew it on paper, and it really helps me figure out exactly how all this needs to come together and how the pieces need to be joined. I consider where the force goes, what holds weight, and what joints need to be stronger than others.

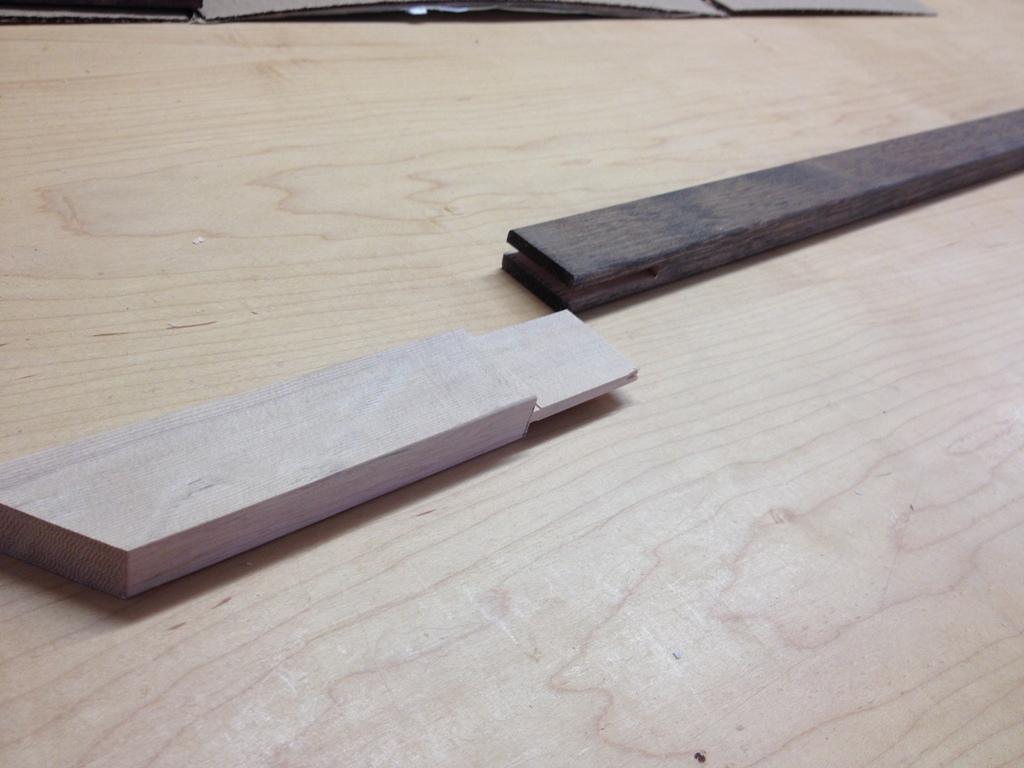

The existing cabinets were plywood boxes nailed together with solid wood frames pinned to the fronts and plywood doors. These will be similar, except that the joinery will be mortise and tenon on the solid frames and good fasteners instead of nails. I fully expect it to last longer than the house.